TiPs Technology

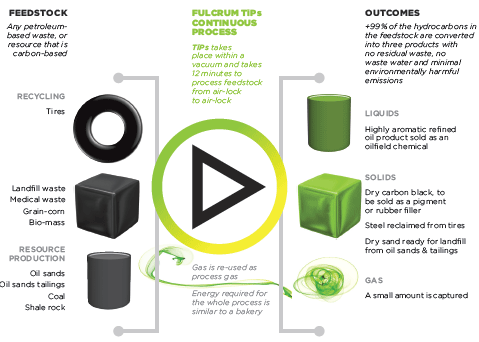

TiPs is both a highly developed and highly functional form of pyrolysis called “Thermal Static Pyrophinic Methodology” (TiPs). The technology – which is protected by both patents and trade secret – has the proven ability to convert scrap tires and other petroleum based waste products as well as primary resource materials – comprised largely of organic, carbon-based matter – into value-added product streams

Fulcrum’s patented ‘TiPs’ technology is a breakthrough method for converting carbon-based feedstocks into value added streams. TiPs is able to process both primary and recycled feedstocks, include; tires, coal, oil sands, shale rock as well as plastics and bio-waste. TiPs has shown consistent results in both commercial and batch quantity tests accrsos these feedstocks consistently demonstrating:

- Low energy consumption

- Minimal greenhouse gas and pollutant emission

- Rapid processing time

- Output of unique chemistry, high aromaticsolvent oils that have a variety of high value uses

- Carbonization of feedstocks in dry ‘carbon black